Introduction: The Composite Challenge and Solution for HSR Materials

The reliable operation of high-speed railways depends on the extreme performance and longevity of every component. Traditional single-metal materials struggle to meet the comprehensive demands: Grounding systems require both good conductivity for current dissipation and high strength for complex geology and deep drilling. Catenary systems demand wires that can withstand immense tension while efficiently carrying current. Signal transmission systems prioritize long-term stability and low loss in harsh environments.

Copper-Clad Steel (CCS), as an advanced bimetallic composite material, provides a systematic solution to these challenges. By metallurgically bonding the excellent conductivity and corrosion resistance of copper with the high strength and toughness of steel, CCS represents an engineering paradigm shift from pursuing single properties to synergistic composite design.

Core Applications: Performance Breakthroughs in Three Systems

The application of CCS in HSR precisely addresses the specific physical and electrical requirements of different systems.

1. Grounding System: Building a Reliable Foundation for a Century

Products: CCS grounding rods, grounding strands.

Performance Breakthroughs:

- High-Strength Deep Drilling: The steel core provides tensile strength ≥600 MPa, enabling vertical drilling dozens of meters deep into hard soil to establish a stable, low-resistance grounding electrode.

- Long-Life Corrosion Resistance & Conduction: The surface copper layer (typically ≥0.25mm thick) ensures good conductivity and forms an electrochemical protective barrier in the soil, with a design life exceeding 30 years for minimal lifecycle maintenance.

- Cost-Effectiveness: Significantly reduces material and maintenance costs compared to pure copper solutions while achieving equivalent or superior performance.

2. Catenary System: The Overhead Artery for Load-Bearing and Current Flow

Products: CCS strands, messenger wires, and armor rods.

Performance Breakthroughs:

- High-Strength Load-Bearing: As messenger or auxiliary wires, the steel core resists wind, ice loads, and system tension, ensuring the geometric stability of the catenary.

- Synergistic Current Carrying: The copper layer effectively shares current load, optimizing network impedance distribution and reducing energy loss.

- Superior Fatigue Resistance: The composite structure effectively absorbs and resists continuous micro-vibrations and mechanical shocks generated by the pantograph of high-speed trains.

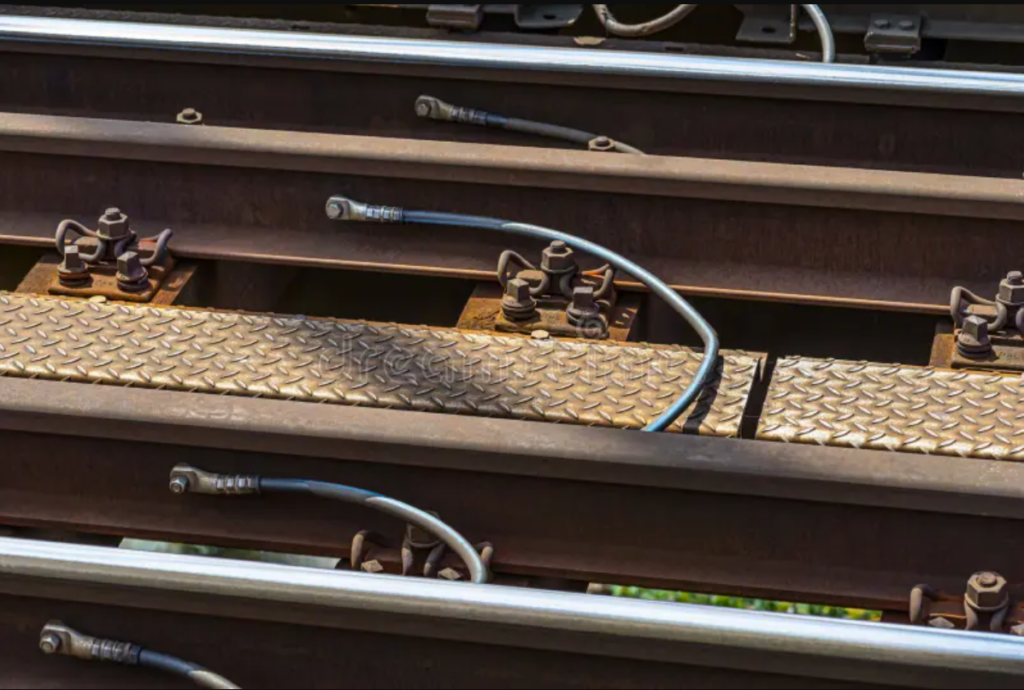

3. Track Circuit & Signaling System: Precise and Stable Neural Conduction

Products: CCS rail bonds (typically sheathed in an insulated, corrosion-resistant jacket).

Performance Breakthroughs:

- Signal Fidelity: The internal copper layer ensures low-loss, high-fidelity transmission of track circuit signals, forming a reliable foundation for the Train Control (ATP) system.

- Environmental Endurance: The overall structure offers excellent resistance to vibration, abrasion, and corrosion from acids, alkalis, and salts, guaranteeing long-term reliability of signal connection points in harsh, humid, or saline environments.

Standard Setters: Defining Industry Performance Benchmarks

Technological leadership is ultimately reflected in the setting of rules. We are not only a manufacturer of high-performance CCS but also a shaper of the international standards for its core raw material. As a principal drafting unit, we participated in the development of the international standard ISO 14811:2024 “Ultra-low carbon high boron steel wire rod for copper cladded wire”, led by the SHOUGANG Group. Simultaneously, we are also the drafting unit for the Chinese National Standard GB/T 38347-2019 “Hot-rolled wire rod of ultra-low carbon steel with high boron”. This signifies our role in defining the highest industry performance benchmarks from the very source of material science, ensuring our products proactively meet all global HSR customer demands for consistency, reliability, and cutting-edge technology.

The successful application of Copper-Clad Steel composites in high-speed railways marks a profound evolution in engineering materials from “usable” to “optimal.” Through sophisticated material composite design and manufacturing processes, CCS provides indispensable foundational material support for the safe, efficient, and intelligent operation of high-speed railways across three critical dimensions: grounding reliability, catenary load-bearing efficiency, and signal transmission stability. With the continuous advancement of material technology and international standards, Copper-Clad Steel will continue to propel high-speed railway infrastructure toward greater safety, economy, and longevity.